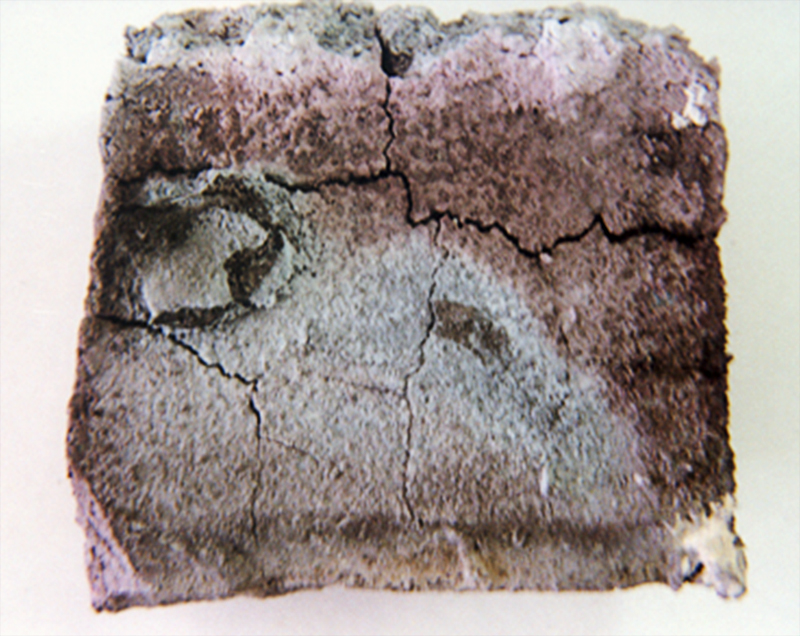

Most refractory issues can be prevented through expert design consultation, proper material selection and stringent quality control during refractory installation, curing and start-up. At REBL, we know this because we have been called in to visit many plants and refineries to inspect refractory problems and find solutions.

The following is a sample of some of the refractory problems we’ve helped solve: